Sealing as a final step in the packing phase

Making a good job of packing and sealing helps to ensure that both the instruments and all people involved, from healthcare operators to patients, are entirely safe.

Once bagging is over, sealing then completes the packing phase and is essential for an effective passage in the autoclave as well as to preserve the sterility of the autoclaved instruments until they are ready to be used (in compliance with ISO 11607-1 and UNI EN 868-5 standards).

How to choose a dental sealing machine

So, it is essential to acquire and use a thermosealing machine for sealing pouches and rolls which will heat seal the packets due for autoclaving, providing a sturdy reliable seal. Which thermosealing machine you choose for your dental practice depends on your specific requirements, but, as a rule of thumb, a good machine should have the following features:

- a roll holder to be mounted on the wall so as to save space in your dental practice

- a safety temperature-control system so that the roll doesn’t get burnt

- audible signals and lights which guide the user while the machine is working

- a compact size to make it easier to work with

As part of its packing and sealing suite, Euronda Pro System offers a vast range of thermosealing machines, especially designed to meet all needs and to deliver the highest standards of safety, quality, ergonomics and traceability.

Euromatic® Plus

This is a rotary thermosealing machine with continuous cycle technology and a sealing speed of 8 m per minute. Ideal for practices with numerous pouches to seal. With its built-in printer, it marks the selected data directly onto the pouch (date, time, operator), saving all sealing-relevant information onto the SD Card or USB key as well.

Euroseal® Valida

This is a bar-based thermosealing machine which not only retains all the best features of the range, but also “validates” the sealing cycle, storing all the information on an SD card or USB key and saving it to the computer via Ethernet and WiFi. The innovative touchscreen display with a user-friendly interface makes it quick and easy to browse the menu and choose one of the pre-set cycles or specify a new one.

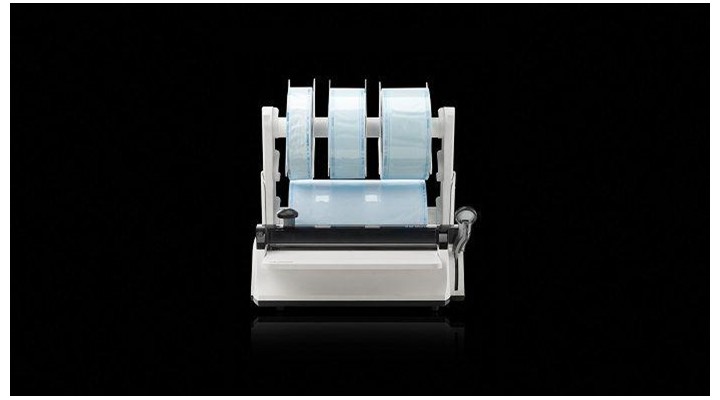

Euroseal®

It is compact, ergonomic and easy to use. The transparent polycarbonate cover makes for easy and accurate operations. The height and depth of the special patented roll-holder can be adjusted to suit requirements, and it can even be wall-mounted. It comes equipped with an anti-roll return blocking system and a safety system to guard against the roll burning.

Euroseal® 2001 Plus

This is an electronic thermosealing machine for continuous cycle processing at a constant temperature. The safe, ergonomic sealing lever is positioned at the front, making it easier to seal surgical packs. Its unique compact design enables it to be placed on a table top or flush-mounted and fitted into standard sterilisation-room furniture.

Euroseal® Infinity

An electronic thermosealing machine for continuous cycle processing at a constant temperature: Euroseal® Infinity is the natural successor to Euroseal® 2001 Plus, from which it has taken and built upon its key elements. Robust, reliable and easy to use, the new design is both eye-catching and functional.

Practical tips on how to properly seal pouches and rolls

If the bagged sterile instruments are to be kept intact until they are ready for use, the sealing process must be done correctly. Here are some important rules:

- The contents must not exceed 3/4 of the packaging volume.

- Seal the pouch and leave a gap of at least 3 cm between the load and the seal.

- Leave a 1-cm gap between the seal and the edge of the paper so that it can be easily opened.

- The width of the sealing strip must be between 6 mm and 12 mm (UNI EN ISO 868-5).

- Protect any sharp ends with special tip covers, having first ensured they are suitable for sterilisation.

- Use an absorbent gauze to mop up any excess oil from lubricated turbines and wands. If the paper gets oil-soaked, the items inside will not be sterilised properly.

- Any instruments in pouches with seals which are clearly burnt or uneven must be packed again.

Getting the right sealing machine means optimising the entire sterilisation process and making it safer. The end result is perfectly sterilised instruments, a more rapid work process and better organisation.

For more information and pricing on the Euronda thermosealer machines and Eurosteril® sterilisation rolls, contact the ICONA team on 1300 442 662