Combine layout improvements with machinery designed to pull long trains of bins and trolleys through narrow spaces, and you've got a highly efficient system that can be further sharpened by individual employees who are doing the picking and packing.

Think vertical rather than horizontal

Often warehouse managers don't fully use the ceiling space they have, sprawling horizontally instead of vertically. If you've got the right lifting gear, it's important to use as much air space as you can when storing pallets and bins.

In doing this, however, it's smart to remember to put goods that are picked less frequently toward the top of a stack.

It's also crucial to put the right piece of equipment or bin in an area where it fits best. By doing this, and creating narrow aisles, you can maximise warehouse floor space.

Materials handling solution for well-organised warehouse

Once you've arranged the floor, it's best to use a compact but powerful mover to pull trains of haulage wagons through tight areas, and tugger trains can be the ideal materials handling solution for this.

Spacepac Industries developed its Tugger Train to be a transport wagon that can move up to 20 trolleys at once.

The machine comes with five attached trolleys that stay extremely stable even when the train is in motion. The product also has a very small turning radius, making it suitable for well-organised and efficient warehouse floor plans.

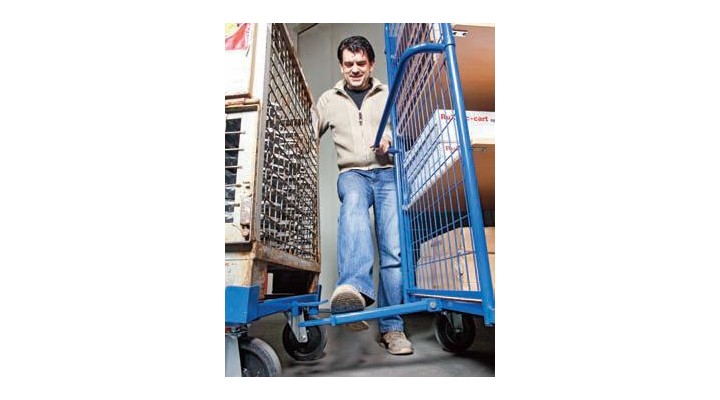

The Train is able to negotiate its way through spaces as small as two metres across, and since the operator can ride along, it saves employees' time and energy.

Tugger Trains allows a single operator to control all functions of the machine, further driving down labour costs and increasing overall employee productivity.